Sealing wood

Whether oak, spruce or rubber tree – we adapt!

Garmisch-Partenkirchen is not just a place for nature and recreation; it is also home to the technical school for carpentry and wood sculpture. This means that we already have a great connection to wood as a material thanks to our location. EGO products are suitable for bonding solid wood as well as wood-based materials in the artistic field.

Our quality products secure the works of master craftspeople through compatible and balanced adhesive and sealing properties. The choice of colours and systems allows woodworking craftspeople to select from a range tailored to their requirements. Contact us, we are sure to have a suitable product for your wood applications.

The correct application of the sealants

The correct sequence of working steps is very important when applying sealants to wood. This is because only those who work professionally and observe the application guidelines will produce a joint that is optimally designed to meet the requirements and guarantee an optimal seal. Bonding is also possible with EGOFLEX 471 or our SMP/MS HYBRID polymers, for example. The following steps must be followed:

- First, the bonding surfaces must be cleaned, as far as possible in the case of raw wood materials. To avoid contamination, surrounding surfaces must be protected by masking if necessary

- Then the backfilling follows with the help of backfilling material. For movement-compensating joints in outdoor areas according to DIN 18540, a closed-cell round cord must be used; for indoor areas, an open-cell round cord is sufficient.

- If necessary, the bonding surfaces are pre-treated with an appropriate Primer.

- Then, the sealant is applied and the string of adhesive is promptly removed or smoothed.

- Finally, if masking has been applied, the adhesive tapes can be removed.

This makes sealing wood with silicone child’s play!

EGO products are produced to a high quality and ensure that the project will last. Furthermore, our wide product range offers the right sealant for every application. You will also find alternative sealants. If, for example, you do not want to use silicone, you can use SMP hybrid, acrylic or Butyl sealants if the application permits this.

Questions about sealing wood

The waterproofing of wooden components or materials can be applied in exterior and interior areas. Outside, balcony elements, gable cladding and roof soffits as well as carport structures and garage door panels are particularly affected. But the various adhesives are also used in the construction of a log building.

Sealants are mainly used for connection joints on windows and doors. Adhesives can be used for built-in elements or furniture as well as for floors, skirting boards and wooden ceilings.

To achieve the perfect results when sealing wood, some tools and other utensils are helpful:

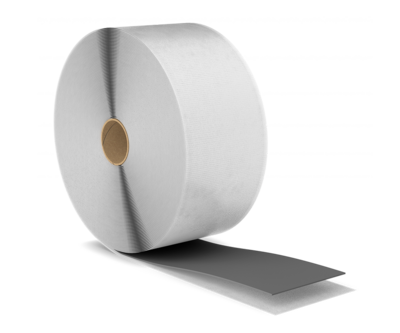

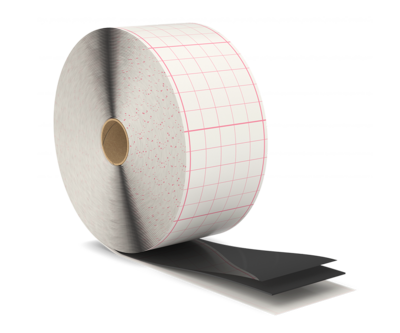

A cartridge press or squeeze gun is necessary to press the adhesive/sealant into joints or connection joints, gaps. When sealing movement-compensating and larger joint depths, you should work with a sealant boundary (backfill material). We recommend the EGO backfill material for this. This is worked into the joint and limits its depth. When applying the sealant into the joint, the backfill material ensures optimum wetting of the joint flanks and, at the same time, prevents 3-flank adhesion.

Excess sealant is easiest to remove with a joint trowel.

EGO products are produced to a high quality and ensure that the project will last. Furthermore, our wide product range offers the right sealant for every application. You will also find alternative sealants. If, for example, you do not want to use silicone, you can use SMP hybrid, acrylic or Butyl sealants if the application permits this.

Sealants are used on a wide variety of wooden components. Skirting boards or connection joints on windows or doors must be sealed with a special sealant to prevent moisture ingress and structural damage such as mould. Acrylic can be used if there are no high moisture and expansion stresses and the joint is to be painted over afterwards.

Silicone is generally very suitable for sealing wooden parts. The natural material wood works, and due to the permanent elasticity of silicone, it can adapt very well to these conditions by absorbing a lot of movement. Sealing with silicone is particularly good in the construction industry for timber or wood materials, as well as in garden and landscape design, furniture construction and much more. Silicone joints are easy to apply and protect joints from moisture Penetration. For applications in the wood sector, we particularly recommend EGOSILICON 151, EGOSILICON 300, EGOSILICON 351, EGOSILICON 360 and EGOSILICON 460.

Acrylic is well suited to sealing joints and connections with lower movement absorption that are not heavily stretched. Light stresses are no problem, these can be compensated by the acrylic sealant. Acrylic can be painted over, but it should not be used in areas in contact with water.

The natural material wood places special demands on sealants/adhesives. Due to their high movement absorption, sealants can compensate for the changes that occur due to swelling and shrinkage of the wood and thus ensure (for example) reliable (structural) sealing.

Special fungicidal silicones are available for weathered bonding in outdoor areas and damp rooms that are permanently exposed to moisture.

Silicones cross-link through atmospheric moisture to form a rubber-elastic end product that bonds and seals. Cross-linking can take several days (2-3 mm in 24 hours) depending on the dimensions of the adhesive joint, humidity and temperature.

The adhesive areas should be clean, in any case.

In the case of wooden windows, sealing is always carried out between the frame and the window. EGOSILICON, among others, is suitable here.

For windows in listed buildings, the glazing rebate can be filled with EGO putty