Putty

Linseed oil putty as a sealant for monument protection

EGO window putties are manufactured using our own Kaltenbrunner mountain chalk from Upper Bavaria. Window putty can be used to adequately seal single glazing in listed buildings without damaging the building. They also guarantee sealing in accordance with DIN 18545: Sealing of glazing with sealants in accordance with groups 1-5 of the "Table for determining the stress groups for window glazing (RoTa)", drawn up by the Institut für Fenstertechnik e. V., Rosenheim.

Notes & overviews

Processing

The processing of our EGO window putty is more than a simple operation - it is a promise of quality. Our high-quality window putty not only gives your wooden windows an attractive appearance, but also provides long-lasting protection. Thanks to its smooth consistency, the putty is easy to apply, can be peeled off cleanly and is perfectly adapted to the glass.

Packaging forms

To ensure optimum handling in a wide range of applications, our window putty is available in various practical packaging forms. For large consumption quantities, we offer buckets that enable easy removal and tidy storage. Our tubular bags are ideal for use with standard squeezing devices and enable precise application. For smaller quantities, we recommend our putty individually packed in handy polybags.

Private Label

Whether in the customer layout or in neutral packaging or in our classic EGO packaging - we find solutions for our customers so that the products find their market. We are happy to advise on application examples & substrates or create the new layout for our customers. We also advise on the legal requirements.

Besonders in Altbauten sind die Fenster eine Schwachstelle in der Wärmeisolierung. Die einfache Verglasung der Fenster hält die Außentemperatur nicht so gut ab wie die Verbundgläser der neuen Fenstermodelle.

UV-, Temperatur-, und Witterungseinflüsse beanspruchen nicht nur die Fenster/Fensterflügel, sondern auch die Kittfuge. Sollte der Fensterkitt bereits porös sein, ist es allerhöchste Zeit eine Sanierung zu planen, um die alten Fenster zu erhalten. Eine Scheibe ist im Fenster eingeklotzt und mechanisch mit Stiften und Klammern gesichert. Der Fensterkitt dient nicht nur zum Abdichten, sondern sorgt zusätzlich für den festen Halt der Glasscheibe.

Gerade bei denkmalgeschützten Gebäuden ist die Erhaltung und fachgerechte Restauration und Sanierung der alten Fenster ein großes Thema. Aber auch in anderen Bereichen wie z.B. ältere Wintergärten und Gewächshäuser werden einfache Scheiben verglast. Aus diesem Grund ist es sinnvoll, sich vorab über die Beanspruchungsgruppe und den geeigneten Fensterkitt zu informieren (Geeignete Fensterkitts zu Beanspruchungsgruppen PDF).

Bei zusammenhängenden Arbeitsvorgängen wie Erneuerung und Überstreichen von Fensterkitt ist es von Vorteil, wenn alle Materialien aufeinander abgestimmt sind. Bei EGO finden Sie die passende Kittspritze, EGOFIX KITT-PRESSE, die unterschiedlichen Kittarten sowie Experten, die Sie gerne beraten.

Eigentlich schon - aber auch nicht. Von EGO gibt es verschiedene Kittarten für unterschiedliche Beanspruchungen und Verarbeitungsgebiete. Für Bleiverglasungen gibt es den leicht verstreichbaren EGO Verstreichkitt. EGOSIT bindet fürs erste schnell ab und benötigt 5-10 Jahre, um komplett auszuhärten. Das macht ihn vergleichsweise langlebig. Gewächshauskitt wird gespritzt – ein Überstreichen ist hier nicht erforderlich. Das EGO Leinölkitt ist der reinste Kitt und besteht nur aus Kreide und Leinöl.

Zudem bietet EGO spezielle Glaserkitts, das SB 11 und SB 25, an. Das SB 25 als weichplastischer Glaskitt eignet sich für alle Beanspruchungsgruppen (1 -5) nach Rota.

EGO Produkte bieten Ihnen eine breite Palette für Ihre Bauvorhaben. Hinzu kommt, dass Sie mit EGO Produkten einen Beitrag zum Klimaschutz leisten. Möglich machts die regionale Kaltenbrunner Bergkreide.

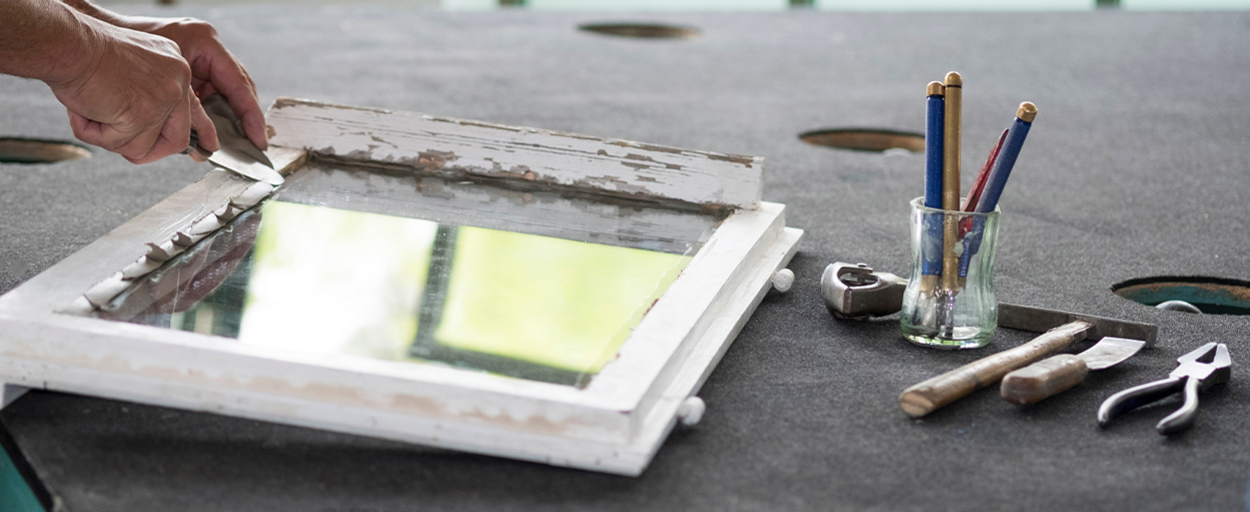

Bevor der neue Kitt aufgetragen werden kann, muss der alte Kitt entfernt werden. Idealerweise wird dazu der Fensterflügel vorher ausgebaut und waagerecht auf die Arbeitsfläche gelegt. Neben den Stiften bzw. Klammern wird die Glasscheibe zusätzlich durch den Fensterkitt gehalten. Um die alten harten Kittreste aus der Fuge bzw. Kittvorlage zu entfernen, empfiehlt es sich einen Schraubenzieher oder ein altes Messer zu benutzen. Diese Arbeit sollte sehr vorsichtig und mit möglichst wenig Druck ausgeführt werden. Wenn der Kitt auf der einen Seite entfernt ist, müssen alle Fugen gründlich ausgesaugt und feucht gereinigt werden.

Um zu verhindern, dass die Glasscheibe beim Entfernen des Kitts zu Bruch geht, sollte der Kitt eine Weile, beispielsweise mittels Heißluftföhn, erhitzt werden. EGO empfiehlt dafür allerdings einen Infrarotstrahler, da es bei unsachgemäßer Anwendung des Heißluftföhns zu Spannungsrissen im Glas oder Lackschäden kommen kann. Nach dem Erhitzen lässt sich älterer Kitt leichter entfernen.

Vor dem Auftragen des neuen Glaserkitts sollte der Untergrund sauber, trocken und fettfrei sein. Saugfähige Untergründe wie z.B. unbehandeltes Holz oder Beton müssen vorgestrichen werden. Das Substrat darf kein Leinöl aus dem Kitt aufnehmen können!

Der Kitt wird mit einem Kittmesser aufgetragen. Jetzt muss genau darauf geachtet werden, dass keine Luftblasen oder Hohlräume entstehen. Am besten arbeitet man abschnittsweise den aufgetragenen Fensterkitt in die Fugen ein. Für eine glatte Oberfläche und gleichmäßige Hautbildung muss die Kittfuge im Anschluss mit einem polierten Kittmesser abgezogen und geglättet werden. Nun haben Sie Zeit für das nächste Fenster, denn der Kitt muss antrocknen.

Wenn Sie Fensterkitt verarbeiten, sollten Sie auf Witterungsbedingungen und die Verarbeitungstemperatur bzw. die Umgebungstemperatur achten. Fensterkitt sollte kühl, trocken und frostfrei gelagert werden. Am besten verarbeiten lässt sich Kitt bei Temperaturen zwischen 5 und 30°C. Auch während der Hautbildungsphase / Trocknungsphase sollten die Temperaturen nie darunter liegen.

Schau mal, wer da... alte Fenster neu einkittet!

Im Internet finden sich zahlreiche Beschreibungen zum Einkitten von Glasscheiben.

Ein Problem, vor dem manche Hobbyrestauratoren stehen können, ist das Öffnen der alten Doppelscheiben von Holzfenstern, besonders bei der Oberlichte.

youtu.be/87DyvojAc9E

Eine gute Anleitung, dafür, wie das Einkitten und Abziehen mit dem Kittmesser aussehen soll, finden Sie hier.

youtu.be/ENXzbblAT5o

Im Video wird bereits das Überstreichen des Fensterkitts angesprochen. Fensterkitt braucht im Vergleich zu anderen Dichtstoffen sehr lange bis er ausgehärtet ist. Durch Temperaturschwankungen kommt es zu Materialausdehnungen und deshalb muss der Kitt plastisch bleiben bzw. ist die lange Aushärtungszeit von Vorteil. Aus diesem Grund sollten zum Überstreichen von Fensterkitt elastische Lacke und Farben verwendet werden.

Die Verarbeitung von Fensterkitt benötigt etwas Zeit, denn nach ausreichender Hautbildezeit (Fingertest) spätestens nach 8 Wochen muss die Kittfase sowie die raumseitige Kittvorlage mit einer wetterfesten Farbe z.B. Acryl oder Alkydfarbe überstrichen werden! Ausnahme EGO Gewächshauskitt - hier ist kein Überstreichen notwendig.

Der Anstrich dient dem Kitt als Schutz vor Luftsauerstoff, um die Oxidation des Leinöls zu verzögern und damit die Lebensdauer der Kittfase zu erhöhen. Daher sollte auch auf eine gleichmäßige Schichtstärke der Farbe geachtet werden. Es sind 1-2 mm Farbe/Lack auf die Glasoberfläche zu streichen, damit Regenwasser besser ablaufen kann und der Kitt vor Luftsauerstoff geschützt ist.

Leinölkitt kann man nicht nur überstreichen, man muss. Frühestens nach ausreichender Hautbildung, spätestens nach 8 Wochen.

Leinölkitt eignet sich besonders für Einfachverglasungen in Holz- und Metallfenstern überwiegend im Denkmalschutz sowie für Gewächshausverglasungen, Abdichtung von Glasdächern und Industrieverglasungen. Auch bei Kunstverglasungen in Blei, Messing oder Leichtmetall ist Leinölkitt die richtige Wahl. Verglasungssysteme nach RoTa Va1.

Zum PDF zu Verglasungssysteme

Die Verarbeitung von Glaserkitt erfolgt zunächst von Hand und/oder mit EGOFIX Kittspritzen. Für Nacharbeiten benutzen Sie am besten ein poliertes Kittmesser. Eine Ausnahme stellt der EGO Verstreichkitt dar. Dieser wird von Hand mit Pinsel oder Spachtel verarbeitet und mit poliertem Kittmesser oder Spachtel nachbearbeitet.

Das kommt auf Faktoren wie Fasen-Geometrie, Temperatur, Sauerstoff, Licht und Luftfeuchtigkeit an. Bis zur Hautbildung dauert es in der Regel einige Tage bis Wochen. Der Kitt muss frühestens nach ausreichender Hautbildung, spätestens nach acht Wochen, überstrichen werden (Ausnahme: Gewächshauskitt). Kittfasen sind in den ersten Jahren Druck und stoßempfindlich.

Nach der Hautbildezeit lässt sich Kitt gut überstreichen. Fensterkitt besteht hauptsächlich aus Calciumcarbonat, also Kreide. Neben der Kreide beinhaltet Kitt Hilfsstoffe, Leinölfirnis und Pigmente. Heutige Kitte sind Naturprodukte und in ihrer Zusammensetzung immer gleich. Es gibt deshalb keine Bedenken hinsichtlich Gesundheit, Natur oder Nachhaltigkeit.

Beim Entfernen des alten Kitts muss man allerdings achtgeben: Vor 1990 wurde Kitt mit Asbestfasern vermengt, was bei Staubentwicklung sehr gefährlich für die Lunge ist. Außer es handelt sich um ein Kittprodukt von EGO – wir arbeiten seit jeher ohne Asbestfasern. Kitte von EGO lassen sich bedenkenlos entfernen.

Der Nachteil von Kitt ist die längere Hautbildezeit und eine notwendige regelmäßige Wartung der Fuge. Um beispielsweise die benötigte weichplastische Eigenschaft zu erhalten, ist je nach Lack eine regelmäßige Wartungslackierung zu empfehlen.

EGO Gewächshauskitt ist für die einfache und preisgünstige Gewächshausverglasungen, Abdichtung von Glasdächern und Industrieverglasungen geeignet. Der Vorteil ist, dass er nicht überstrichen werden muss.

Das kommt auf den Anwendungsfall an. Grundsätzlich empfiehlt sich für die Fensterversiegelung selbstverständlich Silikon. Silikon ist vielseitig, dauerhaft und gut haltbar. Grundsätzlich lässt sich überall dort, wo früher Kitt verwendet wurde, Silikon anwenden. Der Vorteil am Einsatz von Silikon ist eine verkürzte Hautbildezeit. Damit ist die Frühbelastbarkeit von Silikon im Vergleich zu Kitt höher. Silikon lässt sich allerdings nicht überstreichen.

Eine Ausnahme ist der Denkmalschutz. Bei der Sanierung von denkmalgeschützten Fenstern sind die behördlichen Auflagen zu berücksichtigen.

Zum Überstreichen von Leinölkitt benötigen Sie eine wetterfeste Farbe. Infrage kommen dafür beispielsweise Acryl- und Alkydfarbe.

Das kommt auf mehrere Faktoren wie Fasengeometrie, Temperatur, Sauerstoff, Licht und Luftfeuchte an. Bis zu einer ersten Hautbildung kann es Tage oder auch Wochen dauern. Wichtig: Der Kitt muss überstrichen werden. Frühestens nach ausreichender Hautbildung, spätestens nach 8 Wochen.

Das kommt auf die Fasen-Geometrie, Temperatur, Sauerstoff, Licht und Luftfeuchtigkeit an. In der Regel dauert die komplette Aushärtung ca. 5-10 Jahre.