Fenster Abdichtung von EGO für den modernen Fensteranschluss

Window Sealing by EGO for Modern Window Connections

Windows serve multiple functions within the building envelope. They provide natural light and warmth, which are essential for a comfortable indoor environment, while also protecting against wind and moisture. The larger the window, the greater the influx of light and heat into the building. At the same time, the airtightness of windows acts as a vapor barrier, which, if improperly installed, can lead to moisture buildup. High-quality window sealing is essential for creating a cozy and comfortable living space.

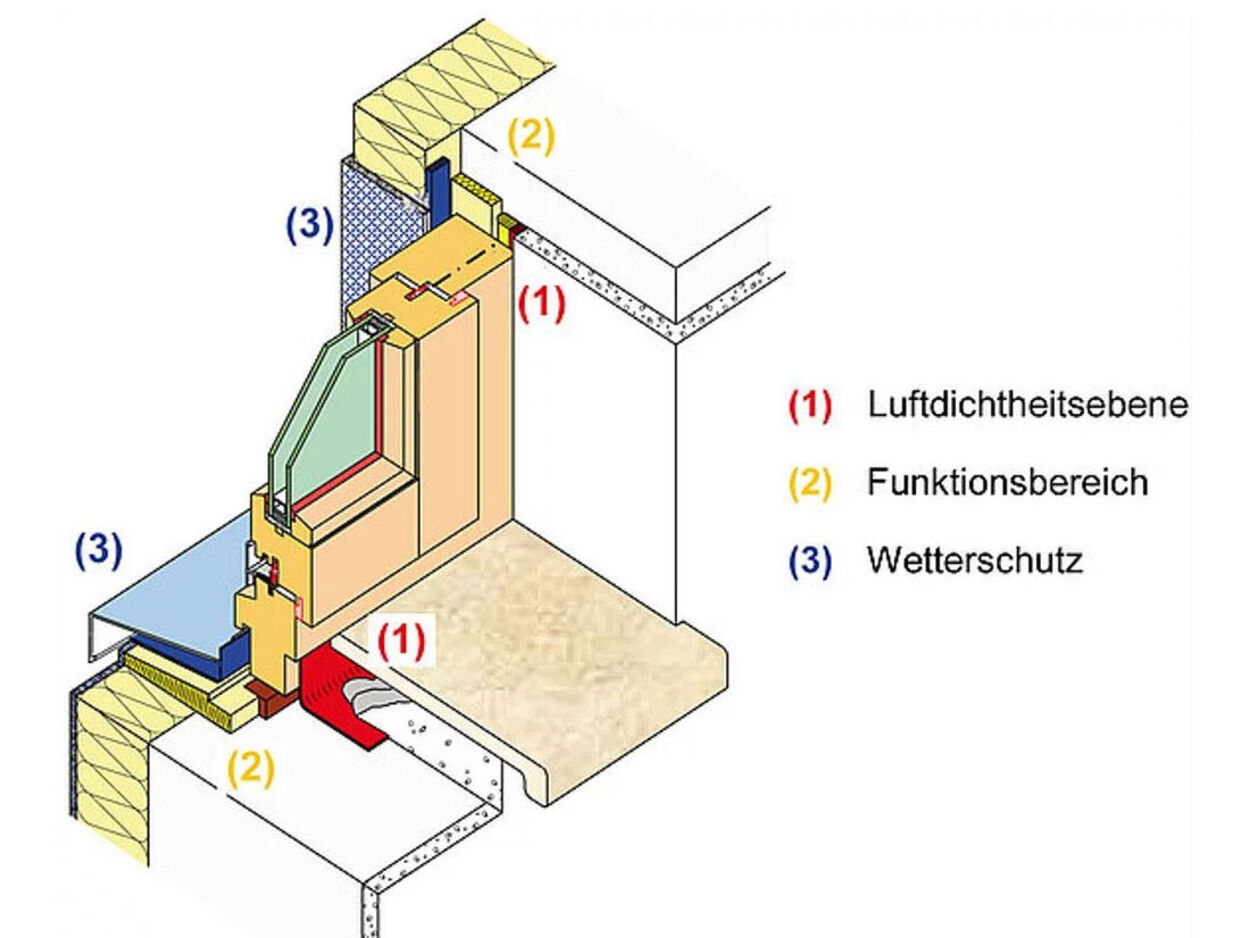

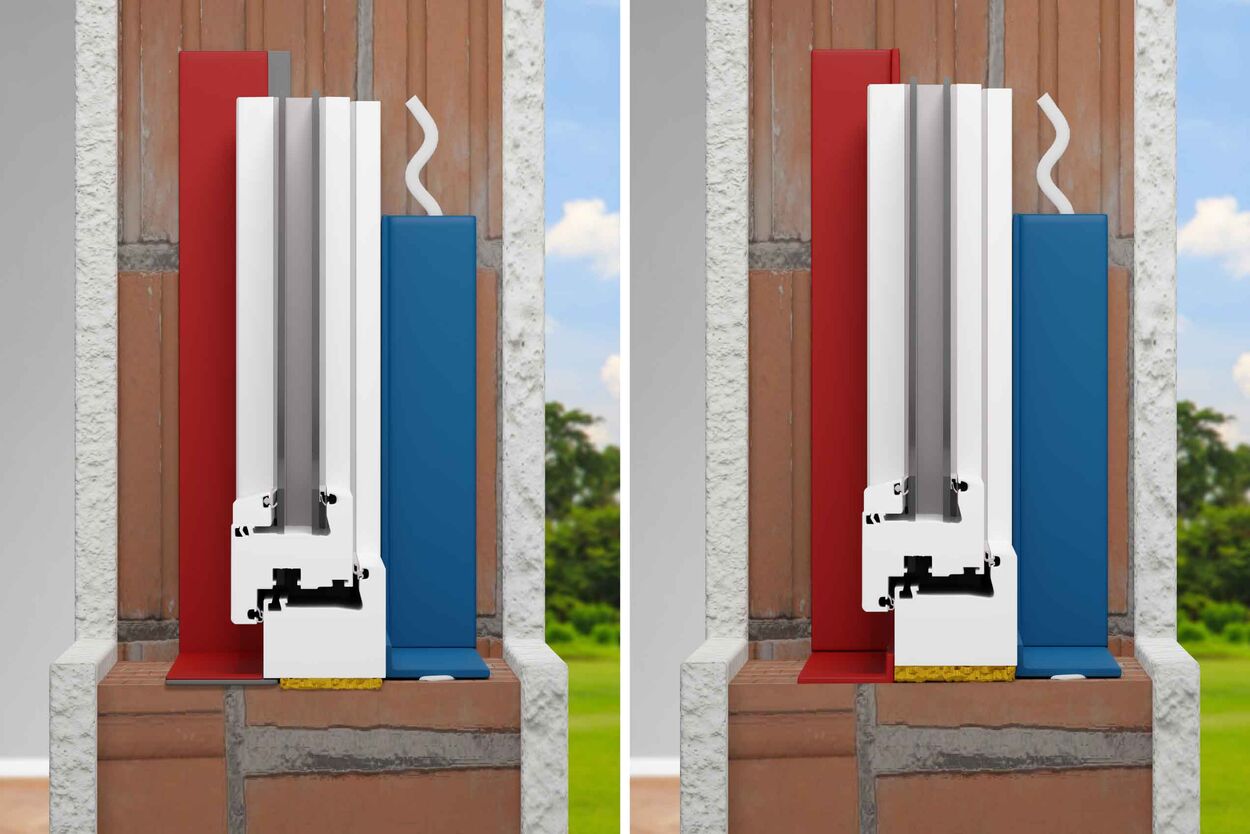

Window sealing in 3 sealing levels

The aim is not only to fulfill the principle of “tighter on the inside than on the outside”, but also to use energy and heat in the interior so efficiently that energy costs can be saved and the thermal/cold bridge has no negative impact on the window. The conditions therefore need to be created in such a way that...

1 innere Dichtebene: Luft- und dampfdiffusionsdicht

...innen möglichst ein hoher sd-Wert für eine Dampfdiffusionsdichtigkeit sorgt.

Dadurch wird das Raumklima erhalten und Wärme wandert n icht durch Fugen und Anschlüsse unkontrolliert nach außen. Gleichzeitig wird die von außen eindringende Kälte im Winter oder Wärme im Sommer abgehalten.

2 mittlere Dichtebene: Schall- und Wärmeschutz

...die Wärme-/Kältebrücke, die innen anliegende Wärme und dadurch entstehende Feuchtigkeit stets nach Außen abgibt.

Da die innere Dichtebene Dampfdiffusionsdicht und die äußere Ebene dampfdiffusionsoffen ist, reguliert sich die Feuchtigkeit stets nach außen.

3 äußere Dichtebene: dampfdiffusionsoffene Regen- und Windsperre

...die Außenabdichtung robust gegen Wetter- und Außeneinwirkung ist, dabei jedoch dampfdiffusionsoffen agiert.

Ebenfalls werden Fremdeinwirkungen wie Tierbefall oder Einbruchsschutz sicher im verputzen Bereich abgedeckt.

...innen möglichst ein hoher sd-Wert für eine Dampfdiffusionsdichtigkeit sorgt.

Dadurch wird das Raumklima erhalten und Wärme wandert n icht durch Fugen und Anschlüsse unkontrolliert nach außen. Gleichzeitig wird die von außen eindringende Kälte im Winter oder Wärme im Sommer abgehalten.

...die Wärme-/Kältebrücke, die innen anliegende Wärme und dadurch entstehende Feuchtigkeit stets nach Außen abgibt.

Da die innere Dichtebene Dampfdiffusionsdicht und die äußere Ebene dampfdiffusionsoffen ist, reguliert sich die Feuchtigkeit stets nach außen.

...die Außenabdichtung robust gegen Wetter- und Außeneinwirkung ist, dabei jedoch dampfdiffusionsoffen agiert.

Ebenfalls werden Fremdeinwirkungen wie Tierbefall oder Einbruchsschutz sicher im verputzen Bereich abgedeckt.

The Solution for a Sustainable and Long-Lasting Window Connection System

Thanks to our certified window sealing systems, windows remain 100% sealed for life. This ensures no heat is lost and no unwanted moisture enters the building. Sustainable and comprehensive products from EGO for sealing every window!

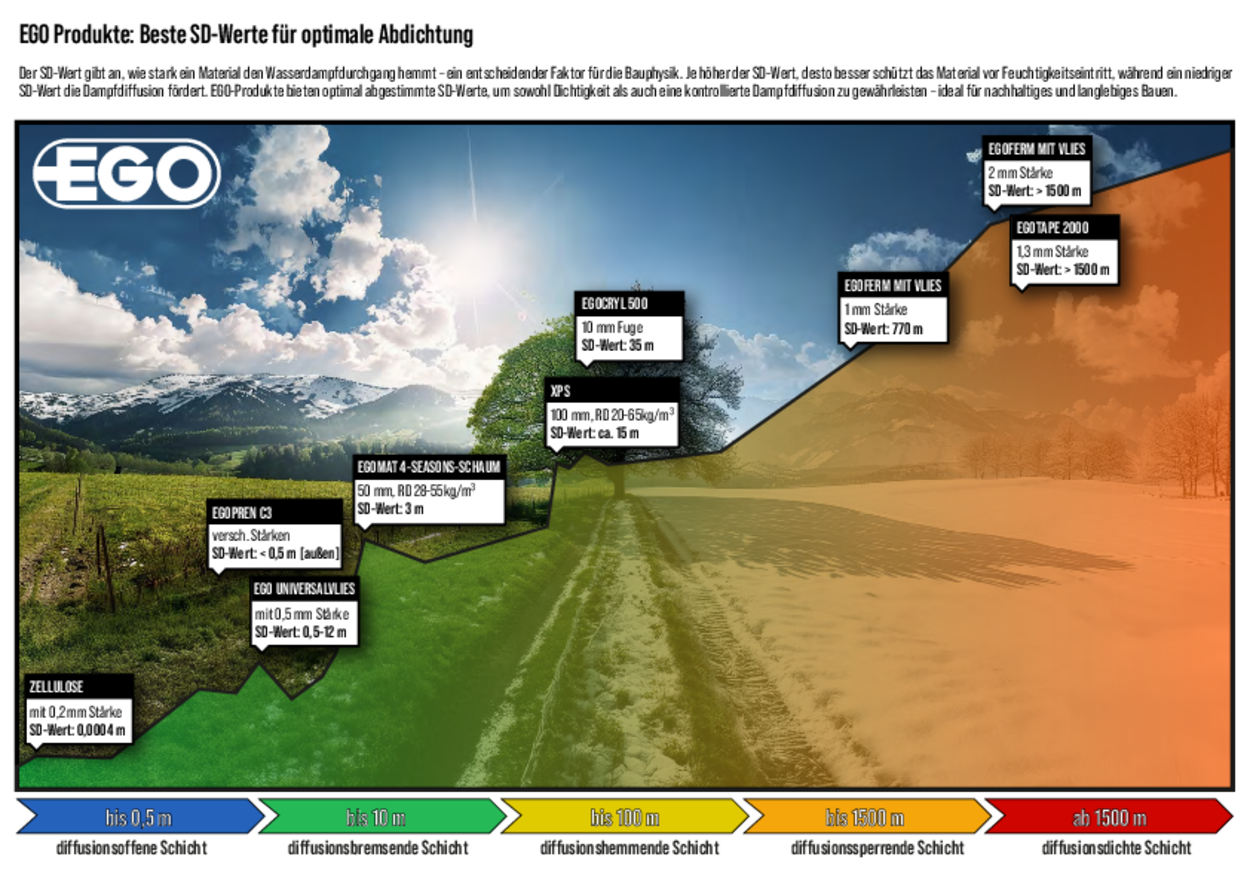

dampfdiffusionsdicht

Mit einem sd-Wert von über 1.500 m erreicht EGOFERM MIT VLIES in der inneren Ebene die höchste Dampfdiffusionsdichtigkeit im Vergleich zu anderen bekannten Abdichtungsprodukten!

3 steps to the perfect window sealing

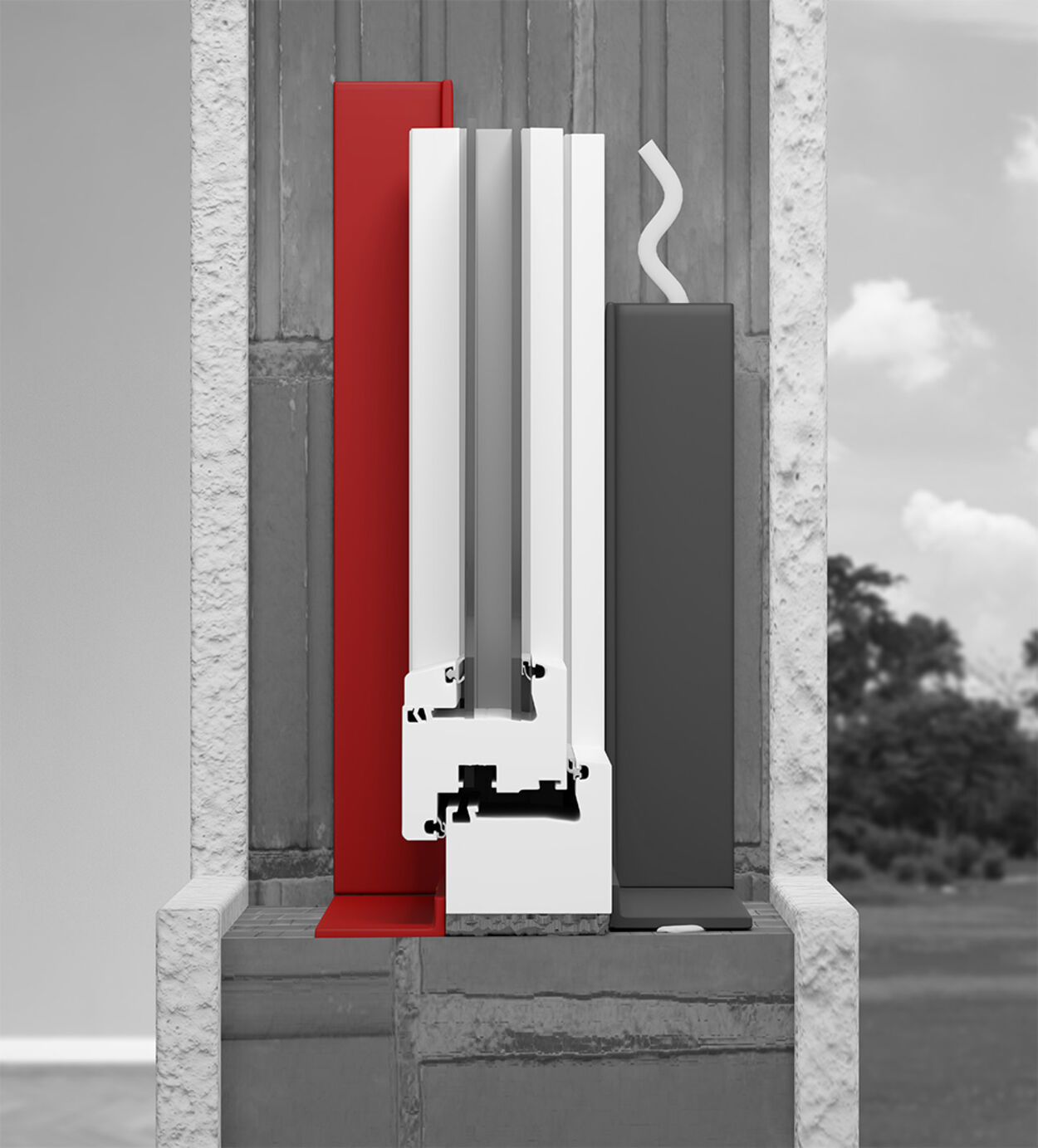

Inner Sealing Layer | Separation of Indoor and Outdoor Climate

- Definition: Diese Trennung muss in einer Ebene erfolgen, deren Temperatur über der für das Schimmelpilzwachstum kritischen Temperatur des Raumklimas liegt. Durch diese Ebene muss Tauwasser an der Rauminnenseite vermieden und das Risiko von Schimmelbildung minimiert werden.

- Umlaufend luftdichter Fugenabschluss: hier muss ein ausreichend bewegungsfähiges Dichtsystem (Dichtbänder, Dichtstoffe, Fugenbänder, Dichtfolien) zum Einsatz kommen. Der luftdichte Fugenabschluss ist dabei auf der Raumseite anzuordnen und muss umlaufend und lückenlos erfolgen.

- Facts Innere Funktionsebene: luftdicht • dampfdiffusionsdicht • überputzbar

Application Tips

- We recommend EGOFERM MIT VLIES, which is easy and convenient to work with during window installation. The product can be plastered over. The Butyl side adhesive bond is applied to the masonry and the window frame.

- As an alternative, the double-sided self-adhesive EGOFERM MIT VLIES DUO can be used. The tape is applied flat with the narrow Butyl strip (on the fleece side) to the window frame. The full Butyl side is then fixed to the masonry. Afterward, the fleece side is plastered over.

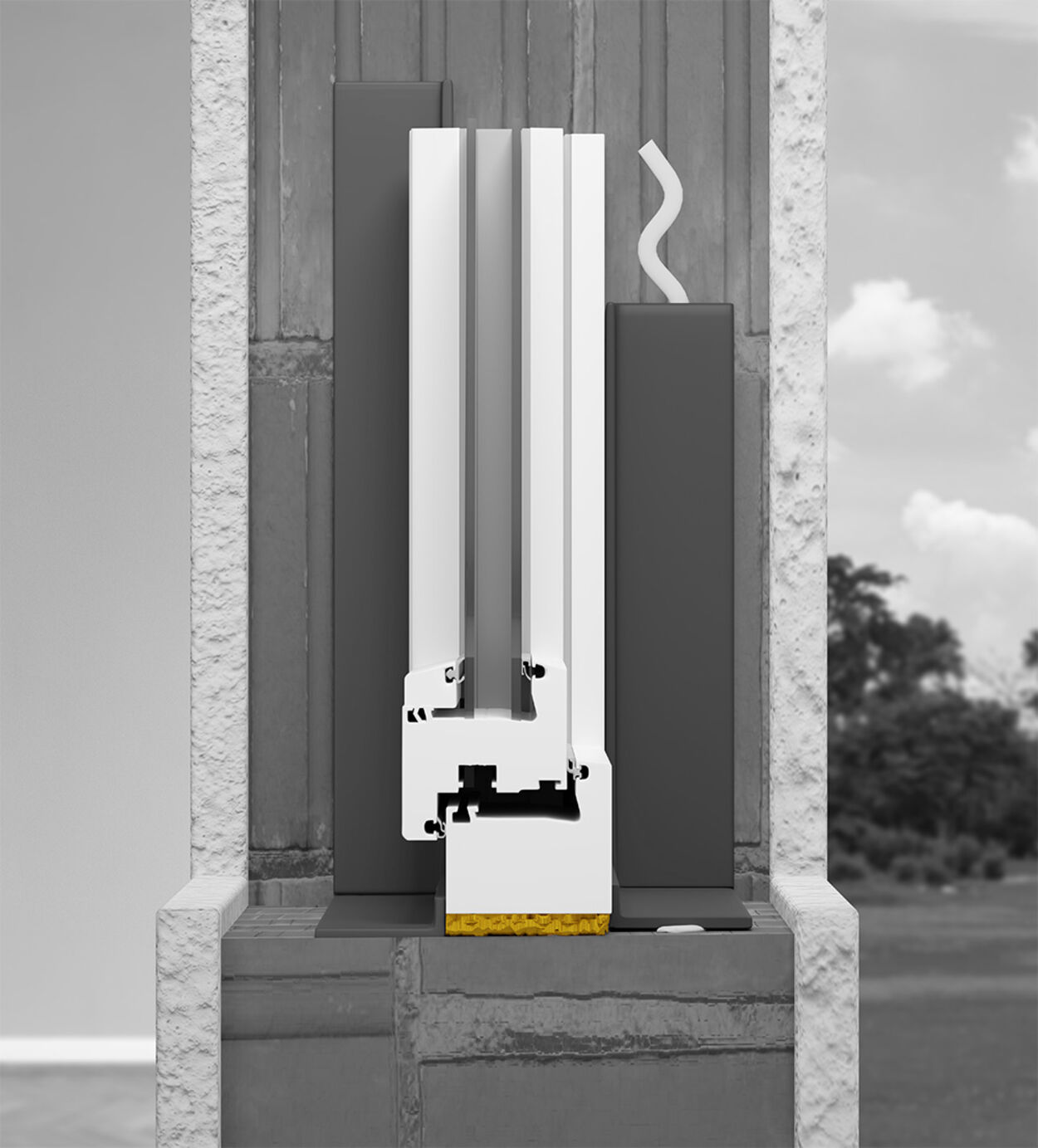

Middle Sealing Layer | Sound & Thermal Insulation

- Function: In this layer, all forces encountered must be securely transferred to the supporting structure via the fastening system.

- Thermal and sound insulation (over an economically appropriate period) are ensured in this layer.

- The main properties to be met are sound insulation and thermal insulation.

Application Tips

- The EGOMAT 4SEASONS PUR WINDOW FOAM is ideal for filling gaps and hard-to-reach areas in the window connection area and is particularly suitable for renovation projects to accommodate different joint cross-sections.

- The EGOPREN C3 JOINT SEALING TAPE is pre-compressed and impregnated, making it a good alternative as a sealing tape. This multifunctional sealing tape meets the requirements for RAL-certified window and door installation, ensures long-term airtightness, and adapts permanently to irregularities in the building components.

Outer Sealing Layer | Vapor-Permeable Protection Against Weather, Rain & Wind

- Definition: The weather protection layer largely prevents the entry of rainwater (driving rain) from the outside. Any rainwater that does penetrate must be controlled and directly drained outward. At the same time, moisture from the functional area must be able to escape outward.

- Driving Rain Resistant Connection: If driving rain exposure is expected due to the installation situation, the outer connection must be designed to prevent uncontrolled water ingress into the structure.

- The main properties to be met are driving rain resistance, windproofing, and vapor permeability.

Application Tips

- Our EGO UNIVERSALVLIES is a one-sided, fully adhesive fleece tape suitable for all common window frames and various masonry substrates. It impresses with its high adhesive strength and is also plasterable.

- For better fixation on difficult substrates or hard-to-reach areas, EGO HYBRID 805 can be used as additional support.

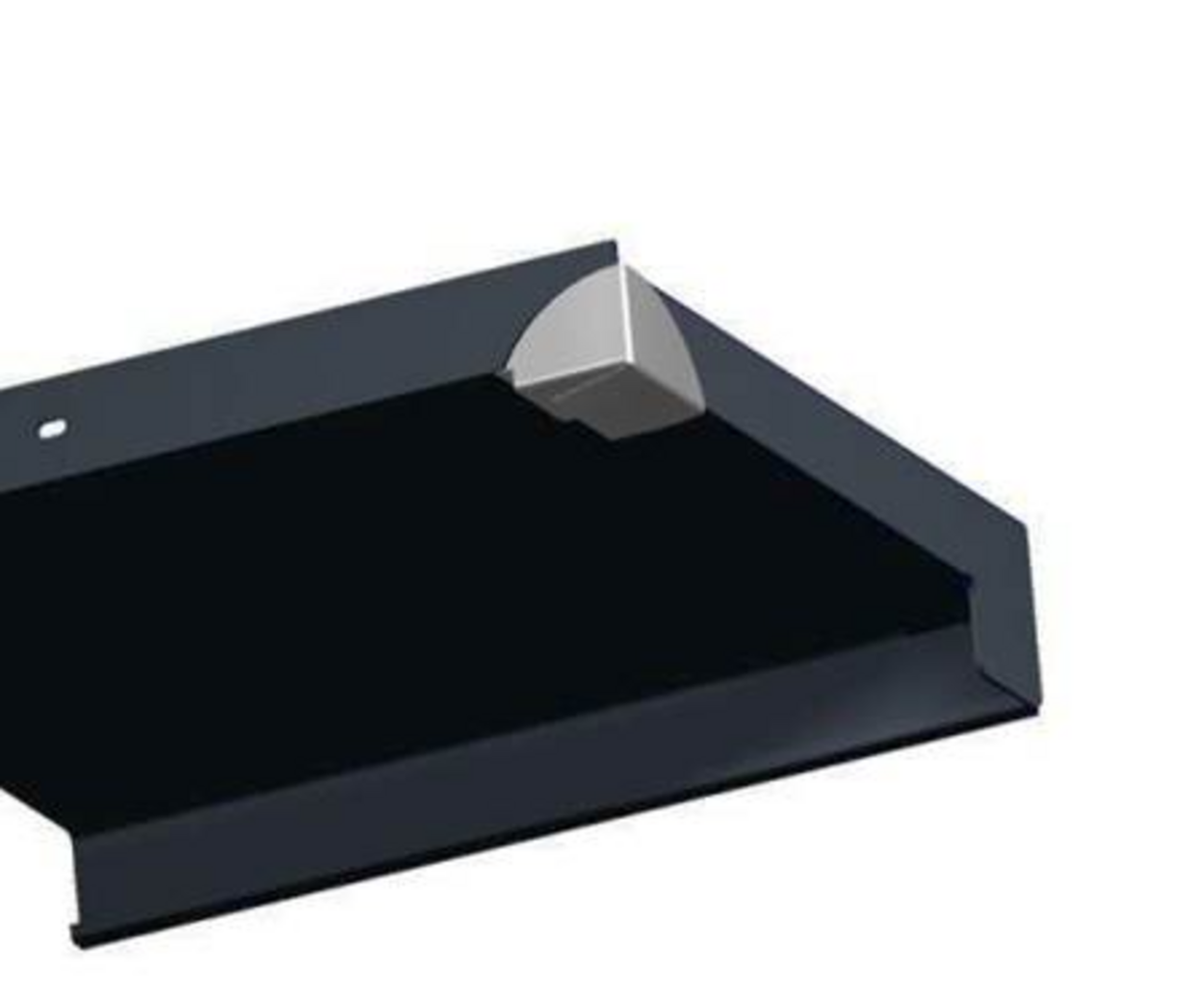

Butylpads: For Sealing Window Sill Corners

The Butyl pads are ready-to-use, sealing Butyl sections specifically designed for sealing in the outer window sill or the water-carrying layer beneath it.

The pads are used to seal the window sill corners in the water-carrying layer, which must be executed as driving rain resistant according to the latest technical standards.

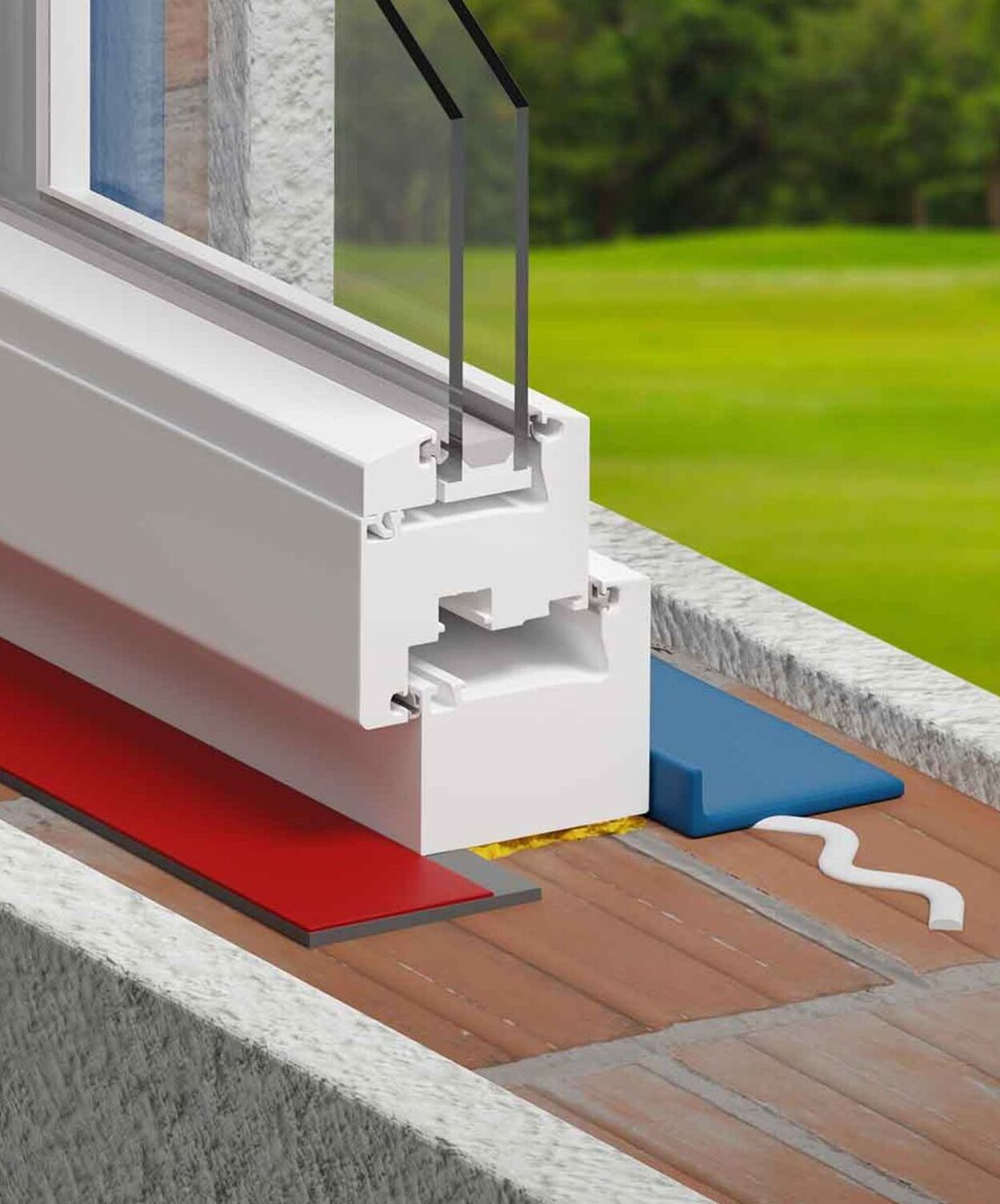

Vibration Dampening and Sound Insulation for the Window Sill!

EGOTAPE 4000 is a high-quality, ready-to-use sealing tape specifically developed for permanent sealing in construction areas with through-screw applications.

The sealing tape absorbs impacts and sounds that affect the window sill, decoupling it from the window frame. This prevents vibration noises, which are transmitted through the window frame and into the interior, ensuring a quieter environment.

Questions and answers about sealing windows

Eine gute Abdichtungsfunktion und Temperaturbeständigkeit sind hier u.a. sehr wichtig. Die Gegebenheiten des Bauwerks müssen bei der Auswahl eines geeigneten Abdichtungssystems berücksichtigt werden. Bei Sanierungen liegen oft bauliche Einschränkungen vor, für die eine fachgerechte Ausführung nach den anerkannten Regeln der Technik berücksichtigt werden müssen um eine dauerhafte Funktionalität gewährleisten.

Die nachstehenden Anforderungen sollte der Dichtstoff erfüllen, um eine langjährige Funktionstüchtigkeit der Fugenabdichtung zu gewährleisten:

- Luftundurchlässigkeit

- UV-Beständigkeit

- Temperaturbeständigkeit

- Chemikalienbeständigkeit

- Alterungsbeständigkeit

Zu berücksichtigen sind auftretende Bewegungen an der Bauanschlussfuge die z.B. durch unterschiedliche thermisch bedingt Längenausdehnungen und Verformungen verursacht werden.

Jede Fassade setzt sich aus 3 Funktionsebenen zusammen.

Die Ebene des Wetterschutzes muss von der Außenseite den Eintritt von Schlagregen verhindern und muss das Entweichen von Feuchtigkeit von innen nach außen gewährleisten.

Im Funktionsbereich muss insbesondere die Eigenschaften Wärme- und Schallschutz sichergestellt werden. Dieser Bereich muss „trocken bleiben” und vom Raumklima getrennt sein

Die Trennebene von Raum und Außenklima muss über die gesamte Fläche der Bauteile und der Außenwand erkennbar sein und darf nicht unterbrochen werden. Die Konstruktion muss raumseitig luftdicht sein. Die Trennung muss in einer Ebene erfolgen, deren Temperatur über dem für das Schimmelpilzwachstum kritischen Raumklima liegt.

Anschlussfugen sind Fugen zwischen zwei Bauteilen, wie beispielsweise zwischen Wand und Fenster bzw. Außentüre diese müssen dauerelastisch abgedichtet werden um die auftretenden Bewegungen an der Bauanschlussfuge die z.B. durch unterschiedliche thermisch bedingt Längenausdehnungen und Verformungen verursacht werden zu kompensieren.

Die thermisch bedingten Längenänderungen der Fensterprofile üben auf den Dichtstoff Dehn-, Stauch- und Scherbewegungen aus. Damit der Dichtstoff diese Bewegungen langfristig aufnehmen kann, wird eine richtig definierte Fugendimensionierung benötigt. Anschlussfugen müssen also unter Berücksichtigung der jeweiligen Bausituation individuell geplant und ausgeführt werden. Die erforderliche Mindestfugenbreite für Anschlussfugen wird bestimmt durch die temperatur- und feuchtigkeitsbedingten Maßänderungen der Rahmenprofile sowie durch die ZGV des eingesetzten Dichtstoffs.

Durch z. B. die Entstehung von Zugluft, Ansammlung von Feuchtigkeit bis hin zu pfeifenden Geräuschen bei Windbelastung. Die Undichtigkeiten entstehen oftmals aufgrund alter Gummidichtungen im Fensterfalz und/oder Fugen zwischen Fensterrahmen und der Fensterbank. Die Anschlüsse zum Baukörperanschluss sollten regelmäßig einer Sichtprüfung unterzogen und auf Beschädigungen und Risse kontrolliert werden.

Für die größeren Temperaturschwankungen im Außenbereich ist ein elastischer Dichtstoff mit einer zulässigen Gesamtverformung (ZGV) von 25 %. Raumseitig kann ein Dichtstoff mit einer ZGV von ≥ 12,5 % verwendet werden.

Es gilt immer das Prinzip „innen dichter als außen“ damit sichergestellt wird, dass in die den Zwischenraum eingedrungene Feuchtigkeit nach außen abwandert. Der Wasserdampfdiffusionswiderstand muss höher sein als bei der Außenfuge und gleichzeitig eine umlaufend luftdichte Abdichtung gewährleisten.

Die Anschlussfuge an der Außenseite muss dauerhaft winddicht, schlagregendicht und witterungsbeständig abgedichtet werden. Der Wasserdampfdiffusionswiderstand muss geringer als bei der Innenabdichtung sein, da das eingeschlossene Wasser nach außen abgeleitet werden soll. Durch diese Bauart wird sichergestellt, dass in die Fuge eingedrungene Feuchtigkeit nach außen abwandern kann.

Anschlussfugen müssen unter Berücksichtigung der jeweiligen Bausituation individuell geplant und ausgeführt werden. Zur Abdichtung eignen sich z. B. EGOFERM MIT VLIES DUO, EGOFERM MIT VLIES und EGO UNIVERSALVLIES sowie z.B. Dichtstoffe wie EGO SMP 818, EGOSILICON 300, EGOSILICON 360.

Die Anschlussfugen zwischen Bauteil und Baukörper müssen langfristig wind-, schlagregendicht und diffusionsoffen ausgeführt werden.

Durch eine BLOWER DOOR MESSUNG. Ein Messverfahren in dem per Über-, oder Unterdruck eine Luftdichtigkeitsprüfung der Außenhülle des Gebäudes durchgeführt wird und somit Aufschlüsse zur Energieeffizienz des Objekts geben. Das Gebäudenergiegesetz (GEG) fordert außerdem, dass die wärmeübertragende Umfassungsfläche einschließlich der Fugen dauerhaft luftundurchlässig nach den anerkannten Regeln der Technik abgedichtet ist.

EGOMAT 2K TOP SPEZIALSCHAUM erzielt im Vergleich zu 1-K PUR Schäumen eine hohe Festigkeit bei gleichzeitiger kontrollierter und schneller Durchhärtung ohne Feuchtigkeitszufuhr und ist bereits nach ca. 10 Min schneidbar und nach ca. 120 Minuten belastbar.

Das ist je nach Produktgruppe unterschiedlich

- -40 °C bis + 100 °C bei SILICON, SMP HYBRID oder EGO Butyl

- -20 °C bis +80 °C bei ACRYLATE

Spezielle Silikone, wie EGOSILICON 300, weisen sogar nachweislich Beständigkeiten von -60 °C bis +150 °C auf.

Neben spritzbaren Dichtstoffen können je nach Konstriktion und den Anforderungen weitere Produkte zum Einsatz kommen wie z.B. imprägnierte Dichtungsbänder, Abdichtungsfolien, Elastomer-Fugenbänder und Fugenprofile.

Ja, für die Bauanschlussfugen außen kann unter Berücksichtigung der jeweiligen Bausituation auch ein Silicon eingesetzt werden.

Für Innenfugen kommen im allgemeinen Acrylate, SMP´s und Dichtungsbänder zum Einsatz.

Ja, aus Gründen des Feuchte-, Schall- und Wärmeschutzes müssen die Fugen im Funktionsbereich umlaufend ausgefüllt werden. Dies ist auch in Bezug auf die Anforderungen des Gebäudenergiegesetz (GEG) notwendig. Als Werkstoffe werden Mineralwolle, Schaumstoffbänder, Kork, Flachs und vor allem PUR-Montageschäume eingesetzt

Das Fugendichtband EGOPREN C1 dient zur äußeren schlagregensicheren Abdichtung von Anschlussfugen im Fenster- und Hochbau zwischen Blendrahmen und Mauerwerk und ist zur Montagehilfe einseitig selbstklebend ausgerüstet und mit einem speziellen Acrylat-Imprägnierungsmittel behandelt. Das in die Fugen verlegte Dichtungsband entspannt sich in Abhängigkeit von Temperatur und Zeit und passt sich dadurch den Fugenbreiten und Unebenheiten der Bauteile an. EGOPREN C1 kann überputzt und überstrichen werden.

EGO UNIVERSALVLIES wird mit einer Überlänge zugeschnitten, die Folie abgezogen und frontal auf den Rahmen geklebt. Als erstes wird unten waagerecht geklebt, dann die beiden Senkrechten und zum Schluss erfolgt die Klebung des oberen waagerechte Abschlusses. Anschließend erfolgt die Klebung auf das Mauerwerk.

EGOFERM MIT VLIES ist ein einseitig selbstklebendes butylkautschukbasiertes Dichtband, das mit einem synthetischen Vlies kaschiert ist und überputzt- und überstrichen werden kann.

EGOFERM MIT VLIES DUO ist beidseitig also wechselseitig klebend und kann somit schon problemlos vor dem Einsetzen am Rahmens angebracht werden. Nach Montage des Fensterstockes in die Mauerlaibung kann ausgeschäumt und EGOFERM MIT VLIES DUO in die Laibung geklebt werden. Mit dem Dichtband ist entsprechend dem Prinzip „innen dichter als außen“ die dampfdiffusionsdichte Abdichtung von Fensteranschlussfugen auf der Raumseite des Fensters zu empfehlen.