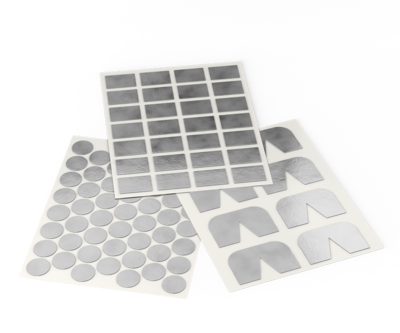

Butyl sealing pads

Precisely fitting seals for demanding applications

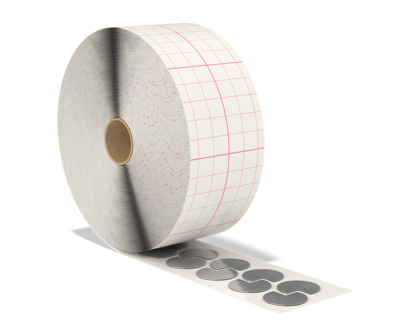

Butyl sealant as a precisely fitting pad for demanding sealing applications. Seals e.g. screws or rivets on window sills, window frames or roller shutter boxes. The Butyl adhesive pads are permanently elastic and strongly adhesive at both high and low temperatures. Pads are available individually on a carrier material, on sheets in DIN A4 or DIN A3 format and on standard rolls in a dispenser box.

Pad variants

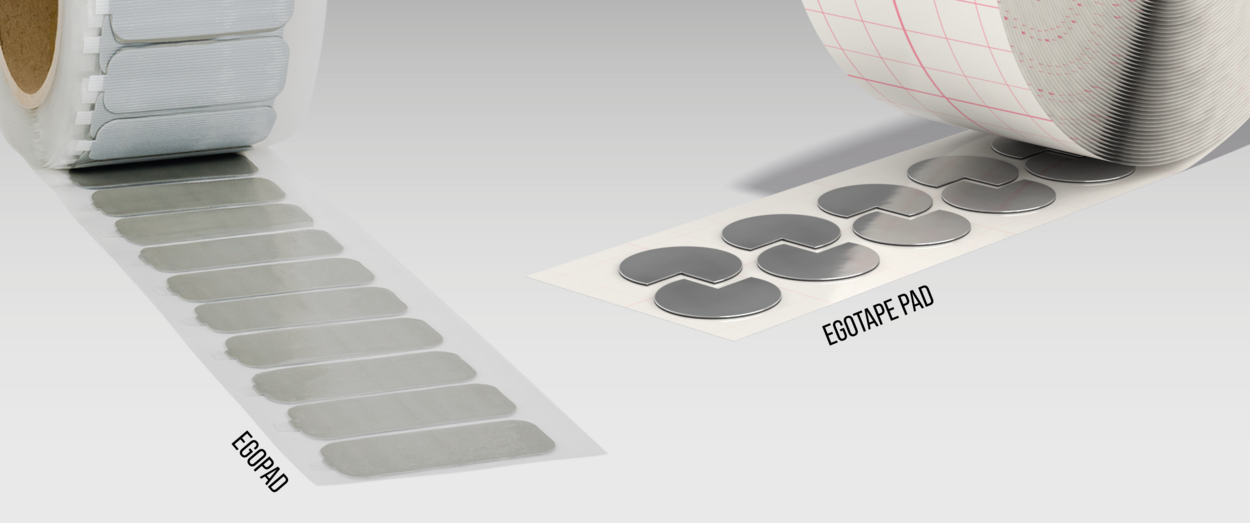

At first glance, the only difference between EGOPAD and EGOTAPE PAD is their design: either with lamination [EGOTAPE PAD] or as a double-sided adhesive PAD [EGOPAD]. Both versions are made of 100% identical materials, PIB-based Butyl [polyisobutylene] and are manufactured to strict tolerances and individually to your specifications. They are durable, UV and weather-resistant and therefore meet the quality standards that you are already familiar with from our Butyl tapes.

Pads on roll or sheet

Punched parts are manufactured on the basis of a primary material using a punching tool. The punching tool is based on a technical drawing and is manufactured precisely to the dimensions. Die-cut parts can be produced either on a roll or on a sheet.

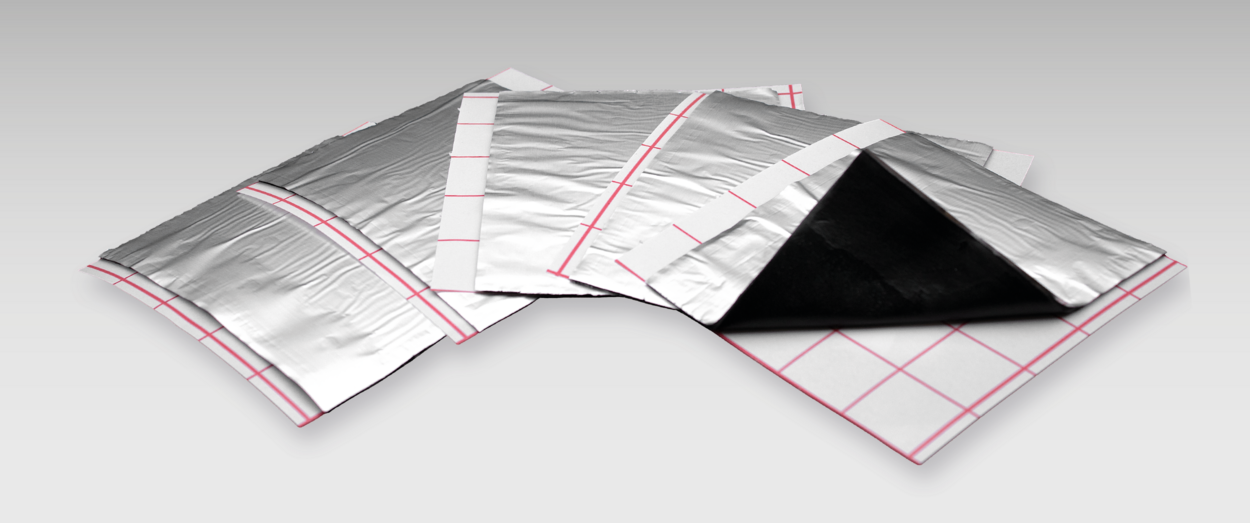

Sheets offer process reliability thanks to a defined number of pads, allow different die-cut parts to be processed on one sheet and are free from creases or roller folds.

Rolls , on the other hand, allow any number of pads to be produced, make it easier to remove the pads and protect them better thanks to their roll shape.

We will be happy to discuss which design - roll or sheet - is best for your application in a consultation.

Pads as punched parts or sections

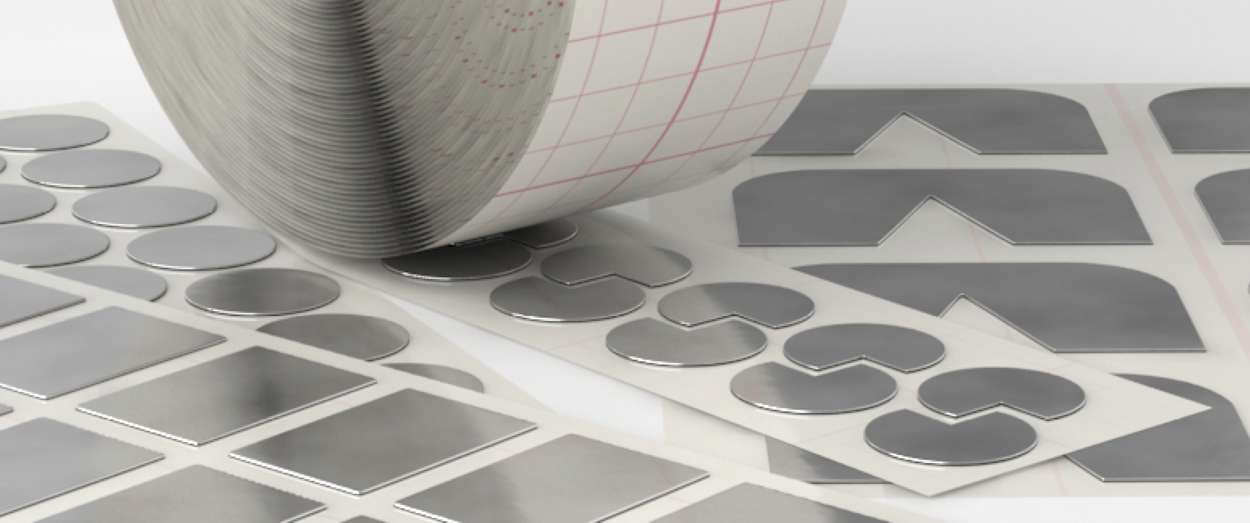

In principle, all shapes and variants of PADS [EGOPADS and EGOTAPE PADS] are possible. Which production method is used - whether punching or extrusion - essentially depends on the shape.

Punched parts allow almost any shape, whether round, square, recessed, stepped or cut out, and also allow two-dimensional special shapes according to drawing specifications.

sections, on the other hand, are designed for rectangular shapes or round cords and can be produced with individual cutting patterns of the carrier materials, for example as sheets, strips or individual designs.

Pads as a section

PADS manufactured using the cut-off process are produced directly on the extruder, with the dimensions being defined by nozzles. Sections can be produced individually or in several strips behind or next to each other. Single sections can be individually assembled as EGOPADs [system component], are suitable for individual sales in retail and can also be packaged separately in a polybag. Strips with several sections, on the other hand, allow a defined number per sheet, easy removal from the roll and the provision of set sizes per sheet.

Punching technology

There are important requirements for the production of stamped parts: A roller core of 76MM, a radius of min. 0.5 mm at all corners and dimensioned part designations by the customer are required. The required punching tool is manufactured within approx. 4-6 weeks, the tool costs are charged pro rata and samples are available free of charge after tool approval. Both die-cutting and through-punching are possible. Important features are the selection of batch qualities, Butyl thicknesses [preferably from 0.8 mm] and Liner qualities, on which we will be happy to advise you.

Packaging forms / Private label

EGOPADs can be selected in various packaging forms, depending on the application. PADs on rolls provide great protection against impact and deformation and are particularly practical thanks to the dispenser carton. PADs on sheets can be stacked neatly, provided the sheet and cardboard size match. Individual pads require more packaging to prevent them from sticking together. PADs as strips make optimum use of the carton, allow defined quantities and offer stable, uncomplicated packaging.

Questions and answers

Butylpads - man könnte sie auch als Pflaster bezechnen - sind geschnittene oder gestanzte Butylstreifen, die zur Abdichtung von speziellen Anwendungen wie Fensterecken oder Rohrdurchbrüchen verwendet werden können. Sie besitzen eine dauerklebrige Dichtmasse, die die Fuge oder Öffnung dauerhaft abdichtet und dämmende und dichtende Wirkung hat.

Im Grunde nein, da aus dem Butylband ein Butylpad entsteht. Man kann auch Butylbänder verwenden und diese dann mit einem Messer oder einer Schere in die entsprechende Form schneiden. Das macht sicher Sinn, wenn die Anwendung einmalig oder speziell ist. Sollte man jedoch die Funktion öfters abdichten wollen, so machen Butylpads immer mehr Sinn, da sie in Menge günstiger und schneller produziert werden, als händisch konfektioniert.

Butylpads werden von Butylband-Herstellern in größeren Stückzahlen gefertigt. Oftmals lohnt es sich daher diese über Baustoffhändler zu beziehen. Standardgrößen um die 50 mm können auch über unseren Onlineshop ab einem Karton bezogen werden, was sich zum Testen für Anwendungen anbietet.

Es gibt Ausführungen mit einseitiger Laminierung (EGO Tape Pad) und doppelseitig klebende Varianten (EGO Pad). Alle nutzen 100 % identisches Butylmaterial, gefertigt exakt nach Kundenspezifikation.

Sie werden u. a. im Fahrzeugbau, Schiffsbau, Luft- und Raumfahrt, öffentlichem Verkehr, Maschinenbau, Haushaltselektronik, Mechatronik, Spezialfahrzeugen sowie Reisemobilen und Caravans eingesetzt.

Butyl Pads sind in nahezu beliebigen zweidimensionalen Formen erhältlich (rund, rechteckig, mit Aussparungen etc.), gestanzt oder als Zuschnitt. Lieferung als Blattware oder Rollen, je nach Stückzahl und Format.

Sie bieten eine dauerhafte, selbstverschließende Abdichtung, sind witterungs- und UV-beständig sowie temperaturständig. Die Dichtigkeit und Beständigkeit entsprechen denen von Butylband-Produkten.

Gestanzte Pads auf Blättern ermöglichen definierte Stückzahlen und formtreue ohne Knickstellen, Rollen bieten Schutz, einfache Entnahme und hohe Flexibilität bei Stückzahlen.

Die Haftung erfolgt physikalisch, verbessert durch festen Andrückdruck. Vor dem Aufbringen müssen Untergründe sauber, trocken und tragfähig sein. So wird eine dauerhaft zuverlässige Abdichtung erreicht.

Ja, EGO Butyl-Tapes sind für den Einsatz im Außenbereich geeignet. Sie sind witterungsbeständig, UV-stabil (je nach Produkt) und behalten auch bei wechselnden Temperaturen ihre Dichtwirkung. Eine mechanische Abdeckung oder Überlappung mit geeigneten Materialien wird empfohlen, um die Lebensdauer zusätzlich zu erhöhen.